Introduction

In any organization, problems are inevitable. But repeatedly fixing the same issues is a drain on time and resources. The key to breaking this cycle isn’t working harder; it’s exploring the reason deeper to find the root cause.

Many organizations struggle with effective problem-solving. A study by McKinsey found that nearly 70% of transformation efforts fail, mostly due to an inability to address underlying root causes.

The 5 Whys analysis is a simple yet powerful tool designed to solve this exact problem, ensuring solutions are effective and lasting.

Finding Root Cause Solutions: A Practical Guide to the 5 Whys Analysis

When a machine breaks down or a project fails, our first instinct is mostly to apply a quick fix. But what if the solution only addresses a symptom, allowing the real problem to fester and recur? This is where the 5 Whys analysis shines. Originating from the Toyota Production System, this lean manufacturing technique is a deceptively simple way to cut through the noise and find the true source of a problem.

What is the 5 Whys Analysis?

The 5 Whys is a straightforward problem-solving method that involves looking at any problem and asking, “Why?” repeatedly until the root cause is discovered. As lean manufacturing pioneer Taiichi Ohno explained, “By repeating why five times, the nature of the problem as well as its solution becomes clear.”

But the number five is a rule of thumb, not a strict rule. It may either fewer or more than five Whys. The goal is to continue the causal pathway until you arrive at a process or system that, when corrected, prevents the problem from happening again.

Why Should You Use the 5 Whys?

The primary benefit of the 5 Whys is its simplicity. It doesn’t require complex statistical analysis or expensive software. It’s a cost-effective tool that:

- Reveals the Root Cause: It helps you see past the obvious symptoms to the fundamental catalyst of the issue.

- Prevents Recurrence: By solving the root cause, you eliminate the problem for good, saving time and money.

- Promotes a Culture of Learning: It encourages teams to think critically and focus on process improvement rather than blaming individuals.

How to Conduct a 5 Whys Analysis: A Step-by-Step Guide

Following a structured process ensures your analysis is effective and fact-based.

1. Assemble Your Team:

Gather a cross-functional team that includes people directly involved with the process. Those closest to the work have the most valuable insights.

2. Define the Problem Clearly:

Be specific. Instead of “the machine isn’t working,” write “Machine A is leaking oil from seal B.” A clear problem statement keeps the team focused.

3. Ask “Why?” and Document the Answers:

Start with your problem and ask why it happened. For each answer, ask “why” again. Document each response with tangible evidence, not assumptions.

4. Know You Have Reached the Root Cause:

You have likely found the root cause when you reach a point where the problem would not recur if this cause were eliminated, and it reveals a fundamental process gap.

5. Develop and Implement Corrective Actions:

Once the root cause is identified, design solutions that directly address it. Assign clear ownership and timelines for these actions.

6. Monitor and Share:

Monitor the situation to ensure the solution works and share the findings across the organization to prevent similar issues.

A Real-World 5 Whys Example:

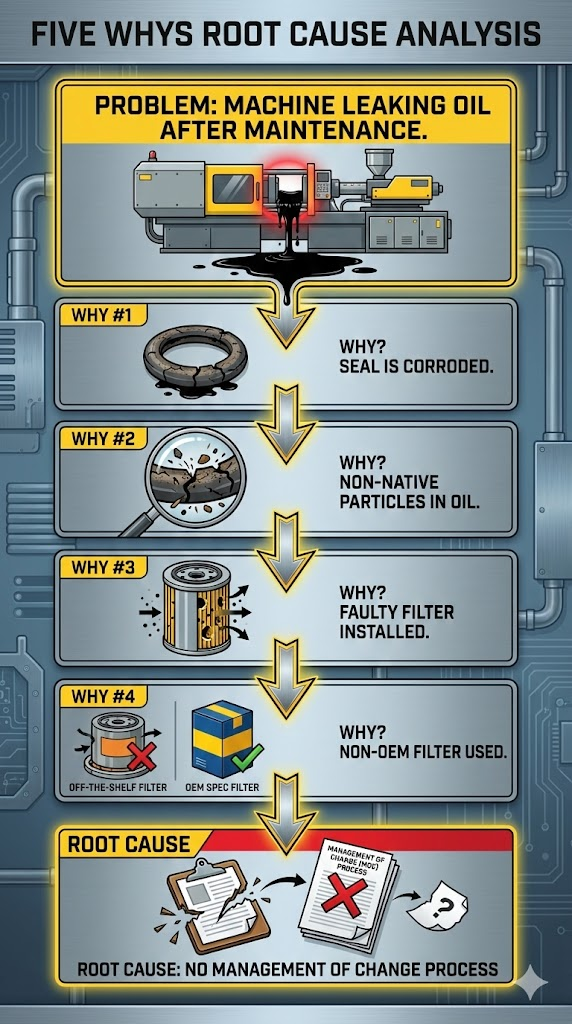

Let’s see it in action, using a classic example from the provided materials.

Problem Statement: A production machine is leaking oil despite recent maintenance. | ||

| Why #1: | Why is the machine leaking oil? | Answer: The seal is corroded and has lost its integrity. |

| Why #2 | Why is the seal corroded? | Answer: There are non-native particles in the oil damaging the seal. |

| Why #3 | Why are there non-native particles in the oil? | Answer: The recently installed filter is not functioning properly. |

| Why #4 | Why is the filter not functioning properly? | Answer: The filter did not meet OEM specifications, leading to a poor fit. |

| Why #5 | Why was a non-OEM filter installed? | Answer: There is no formal “Management of Change” process for part changes, so the technician lacked the proper information. |

Root Cause: A missing “Management of Change” process. | ||

Solution: The immediate fix is to replace the filter. The long-term, root cause solution is to implement a formal process for part changes to prevent this error in the future. |

Best Practices and Common Challenges:

To get the most out of the 5 Whys, keep these tips in mind:

- Focus on Process, Not People: The goal is to fix the system, not to assign blame.

- Base Answers on Facts: Use data logs, witness statements, and physical evidence; not opinions.

- Don’t Stop at Symptoms: If your answer sounds like a final solution (e.g., “the operator was tired”), you likely need to ask “why” again.

The main challenge is that not all problems have a single, linear cause. In more complex scenarios, the 5 Whys can be combined with other tools like Fishbone (Ishikawa) Diagrams to map out all potential causes.

How Can Proper Knowledge Help to Master the 5 Whys Technique for Root Cause Analysis?

If you are a professional aiming to master the 5 Whys Analysis for effective root cause problem-solving, here are the Top Reasons to Choose CSM training: It provides a structured, agile framework that teaches you not just the technique, but how to facilitate it within a team to drive continuous improvement and prevent issues from recurring.

Conclusion:

The 5 Whys analysis is a powerful yet accessible tool that empowers every team to become a problem-solving unit. By committing to looking beyond the surface, you can transform recurring headaches into opportunities for lasting improvement. The next time a problem arises, gather your team and start asking “why?”; you might be surprised at what you discover.