Box build assembly is a comprehensive process that goes beyond standard printed circuit board (PCB) assembly. It involves integrating fully assembled PCBs into enclosures or “boxes,” along with wiring, connectors, power supplies, and other components required to create a complete electronic system. This stage is the bridge between PCB production and final product delivery, ensuring that all electronic and mechanical elements work together seamlessly.

Unlike basic board-level assembly, box build assembly includes the design, fabrication, and integration of various components into one cohesive product. It’s used across many industries, including telecommunications, medical, industrial automation, consumer electronics, and aerospace, where reliability and performance are paramount.

The Process of Box Build Assembly

The box build assembly process is highly customised, as it depends on the specific product design and customer requirements. However, it generally includes several core stages that ensure functionality, precision, and quality.

1. System Design and Planning

Before production begins, engineers review the customer’s product schematics, 3D models, and mechanical layouts. This stage involves identifying materials, enclosure designs, and wiring specifications. Proper planning ensures efficient assembly and reduces potential integration issues later.

2. Subassembly and Wiring

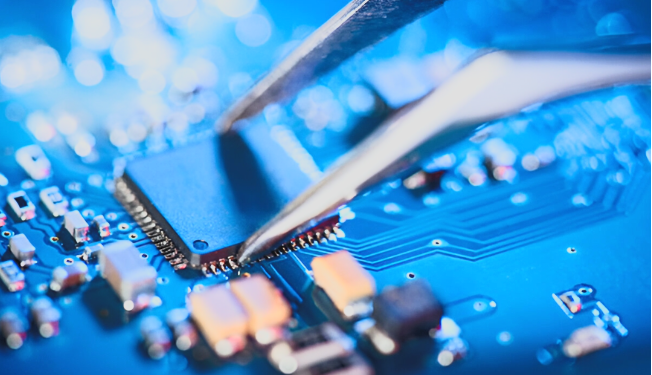

In this stage, internal components such as PCBs, cables, and harnesses are pre-assembled and organised according to the product’s configuration. Wire routing and cable management play a key role in maintaining system integrity and ease of maintenance.

3. Mechanical Integration

The subassemblies are installed inside enclosures, which can be metal, plastic, or composite materials, depending on the application. Engineers mount displays, switches, fans, and connectors while maintaining strict alignment and grounding standards to ensure durability and electrical safety.

4. Software and Firmware Installation

For products that require digital control or communication, the firmware or operating software is programmed during assembly. This integration ensures that the system operates as intended once powered on.

5. Functional Testing and Quality Assurance

Once the build is complete, each unit undergoes rigorous testing to verify electrical connectivity, mechanical integrity, and performance. These tests can include power-on checks, signal verification, environmental testing, and functional simulations.

By the end of this process, the final product is ready for packaging, shipment, and immediate use, saving clients significant time and resources.

Benefits of Box Build Assembly

Choosing box build assembly offers numerous advantages, especially for manufacturers looking to simplify production and ensure high-quality outcomes.

Streamlined Manufacturing

By outsourcing box build assembly, companies can consolidate multiple stages of production—PCB assembly, wiring, enclosure fitting, and testing—into a single managed process. This reduces coordination complexity and accelerates product delivery.

Improved Quality and Reliability

When a single provider handles both PCB and box build assembly, they can maintain strict quality control throughout every stage. This leads to higher consistency, fewer errors, and improved product reliability.

Cost and Time Efficiency

Box build assembly reduces the need for multiple suppliers and production transfers. The integration of all manufacturing steps under one roof leads to lower logistics costs, faster turnaround times, and reduced labour expenses.

Customisation and Scalability

Whether producing low-volume prototypes or large-scale commercial units, box build assembly is adaptable. Manufacturers can easily adjust configurations, materials, and testing protocols to meet evolving market demands.

End-to-End Testing and Certification

Comprehensive testing ensures the final product is ready for immediate deployment. Many providers also offer certification support, ensuring compliance with international standards such as ISO, IPC, or UL.

Applications of Box Build Assembly

Box build assembly is widely used in industries where complex electronics and mechanical components must be integrated into a reliable enclosure. Common applications include:

- Telecommunication Equipment: Routers, switches, and network control units.

- Medical Devices: Diagnostic instruments, imaging systems, and monitoring equipment.

- Industrial Automation: Control panels, sensors, and power systems.

- Aerospace and Defence: Communication devices and navigation systems.

- Consumer Electronics: Home automation units, charging stations, and entertainment devices.

Each application requires a unique configuration, but the principles of precision, reliability, and efficiency remain the same.

Importance of Partnering with Experts

Selecting a skilled manufacturer for box build assembly is essential for ensuring high product quality and operational reliability. The best partners combine engineering expertise, advanced equipment, and comprehensive testing capabilities. They can handle complex cable harnesses, mechanical integration, and complete system validation with precision.

An experienced provider not only assembles but also optimises designs for manufacturability (DFM), improving product consistency and reducing overall costs. Moreover, having access to in-house capabilities—from PCB assembly to full box integration—allows for seamless project management and shorter production cycles.

Why Box Build Assembly Matters in Modern Electronics

As electronic devices become more sophisticated, box build assembly is no longer an optional step—it’s a necessity. It brings together electrical, mechanical, and software engineering disciplines into one process. With the rise of automation, IoT devices, and embedded systems, integrated assembly solutions help manufacturers keep up with demanding schedules while maintaining performance standards.

Furthermore, box build assembly supports sustainability by reducing waste and streamlining production. It enables better control over materials and components, which contributes to improved efficiency and environmental responsibility.

Conclusion

In the competitive electronics industry, box build assembly plays a vital role in transforming individual PCBs and components into complete, market-ready products. Its combination of precision, scalability, and efficiency makes it an essential service for manufacturers seeking consistent quality and reliability.

To achieve the best results, it’s crucial to collaborate with a professional partner that offers a comprehensive PCB assembly service. A trusted provider will ensure every stage—from board fabrication to full system integration—is executed to perfection, allowing your products to meet the highest global standards for performance and reliability.